Vision

The vision of BARGEM is to become the leader in battery group technologies in Turkey and a key contributor to global development, driven by a customer-focused approach.

Mission

BARGEM is committed to growth through an innovative management system, aiming to develop high-quality and innovative products based on the principles of flexibility and customer orientation.

Establishment and Purpose of BARGEM

Founded under the registered trademark “BPM Battery Solutions” in 2020, Birikim Pilleri has been providing R&D support to leading manufacturers in Turkey, supplying locally designed battery management systems (BMS) and battery packs for the electronic products they develop.

As the only institution in Turkey offering battery pack assembly services with dedicated quality control processes, Birikim Pilleri continuously aims to enhance customer satisfaction. With the growing global significance of battery technologies, the company sees the development of innovative and nationally valuable battery systems as a strategic objective. The focus is on delivering differentiating and competitive solutions for applications in light electric vehicles, rechargeable home appliances, security, lighting, manufacturing, electronics, and healthcare.

Birikim Pilleri’s R&D Center, known as BARGEM, is the first R&D center in Turkey to specialize in battery pack and battery management system development.

Operating under the motto “Manage energy, manage the future,” BARGEM leads Turkey’s research and development efforts in battery cells, battery packs, battery management systems, and energy storage technologies.

With a team of over 30 researchers, BARGEM has been delivering industry-leading, high-impact projects since 2020.

Specializing in battery pack design and manufacturing for micro-mobility, defense, and aerospace sectors, Birikim Pilleri, through BARGEM, is committed to supporting Turkey’s technological advancement and sustainable future.

BARGEM Focus Areas Include:

Developing custom battery packs, protection circuits, battery management systems (BMS), thermal management systems, and chargers

● Creating customer-specific, high value-added, and innovative products

● Exploring technical and economic alternatives to materials used in current products

● Benchmarking competitors and following emerging battery technologies

● Collaborating with universities, public institutions, and private sector organizations to develop products based on customer demands

● Offering testing, analysis, and characterization services for new battery technologies

● Advancing domestic technology and know-how

International Recognition

Officially approved as an R&D center in December 2022, BARGEM and Birikim Pilleri are now members of the European Battery Alliance (EBA 250). As a solution and development partner for customized battery needs, Birikim Pilleri continues to be a key contributor to a greener and more sustainable world through its BARGEM projects.

Operating in a 4,000 m² closed facility with its own integrated R&D and manufacturing center, Birikim Pilleri is a globally capable Turkish company with operations that span worldwide.

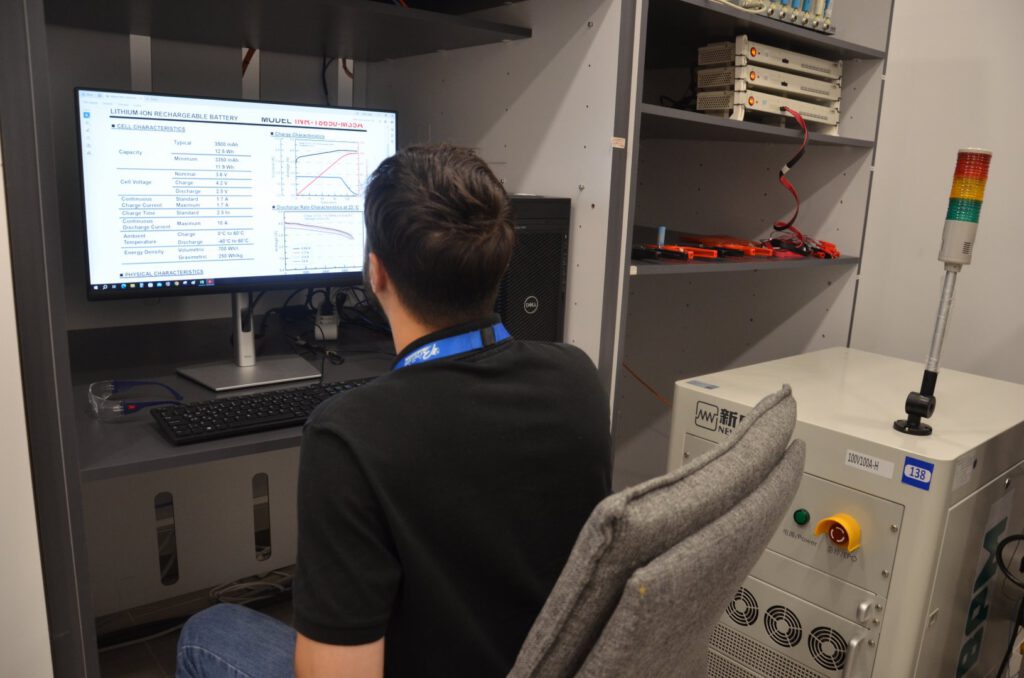

BARGEM Laboratories

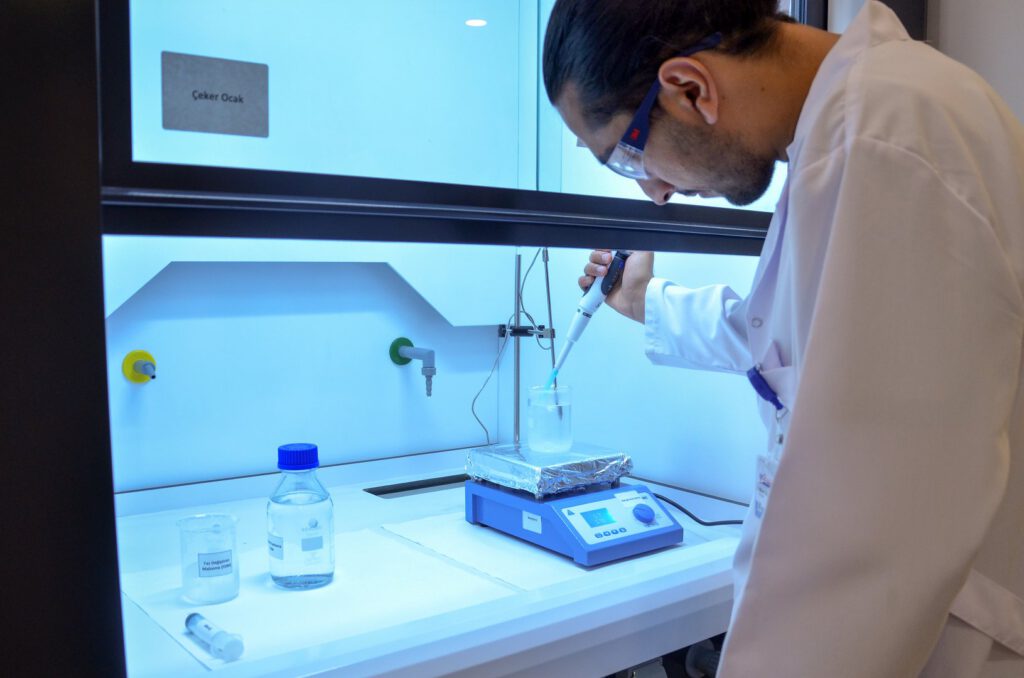

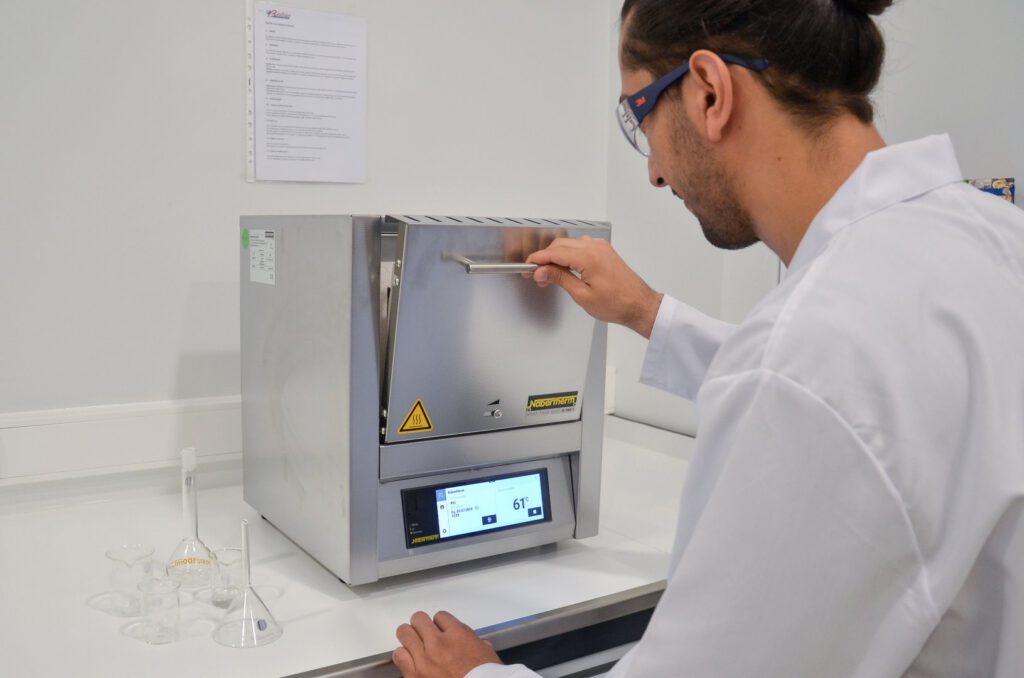

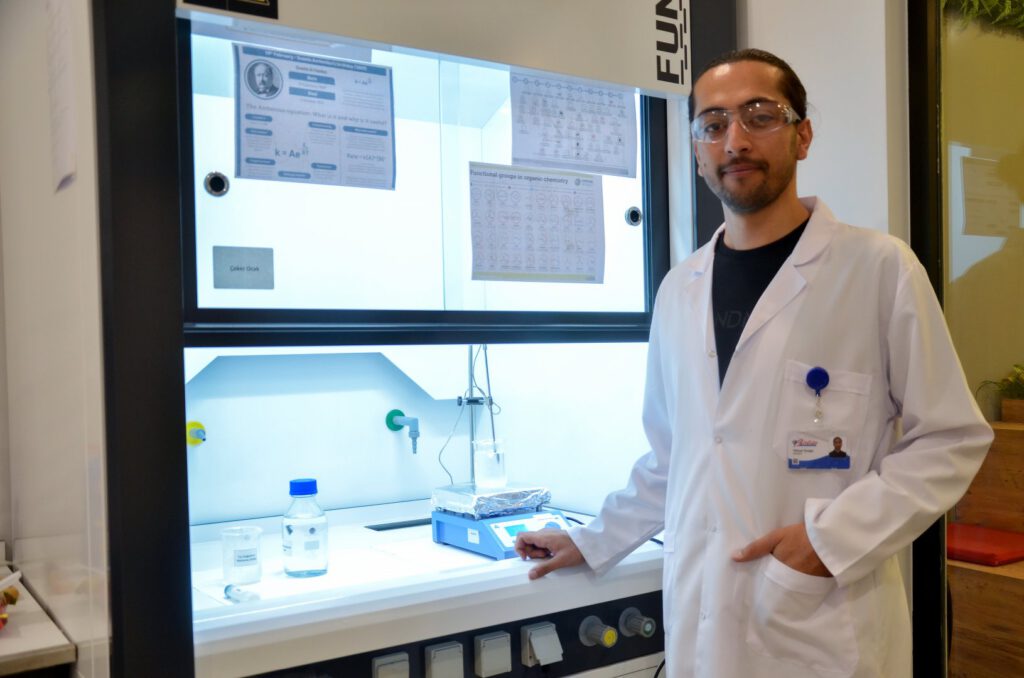

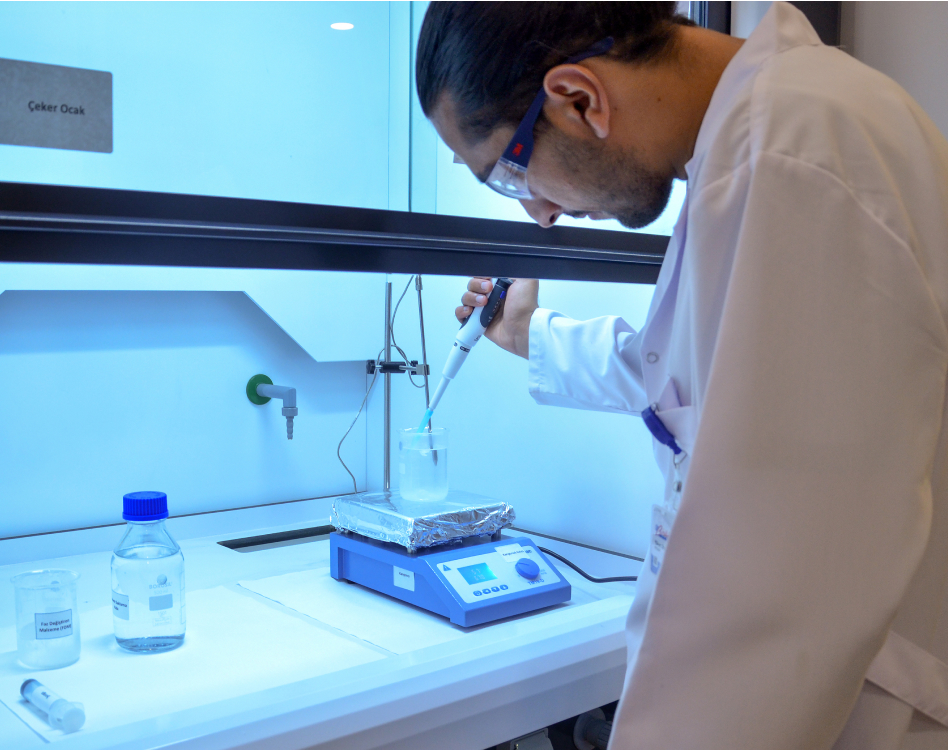

Chemistry Laboratory

Advanced research is conducted using high-quality materials.

Thermal analysis of materials is carried out in the Chemistry Lab, enabling the identification and resolution of thermal issues.

Particular focus is placed on the development of international-level techniques for flame-retardant applications.

Thermal Management Laboratory

This lab specializes in material characterization and the development of innovative thermal management solutions.

It focuses on integrating advanced materials with existing materials and analyzing the thermal conductivity of newly developed products.

Real-world environment testing is conducted to simulate operational conditions.

Using our state-of-the-art 3D prototyping machine, near-real prototypes are created to perform comprehensive analyses and pre-production validations of developed products.

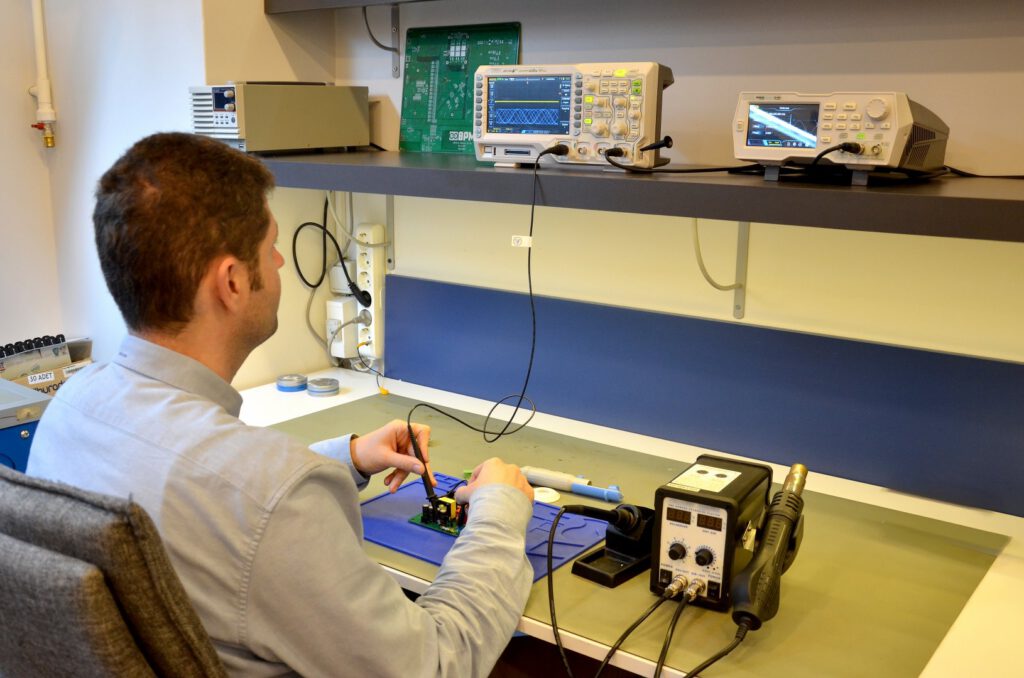

Batarya Yönetim Sistemi (BMS) Laboratuvarı

The BMS Lab designs advanced battery management systems for a variety of applications and performance goals.

Using sophisticated software tools such as SolidWorks and COMSOL, battery management systems are designed, modeled, and analyzed in detail.

These high-level analysis platforms are used to simulate the thermal performance of batteries of various sizes and chemistries.

Smart battery management algorithms and systems are developed specifically for electric vehicles and renewable energy storage applications. Custom-designed BMS circuit boards are produced in-house using the SMD assembly machine located within the R&D Center, and undergo rigorous testing.